Work Process

Operators need to manage critical data about the asset across the various life cycle states of FEED (Front End Engineering and Design), construction, installation, in-service, and decommission. The information is used for repair and replacement, but also used to understand the current and future state of the asset to address safety, environmental, and production risks.

Problem Statement

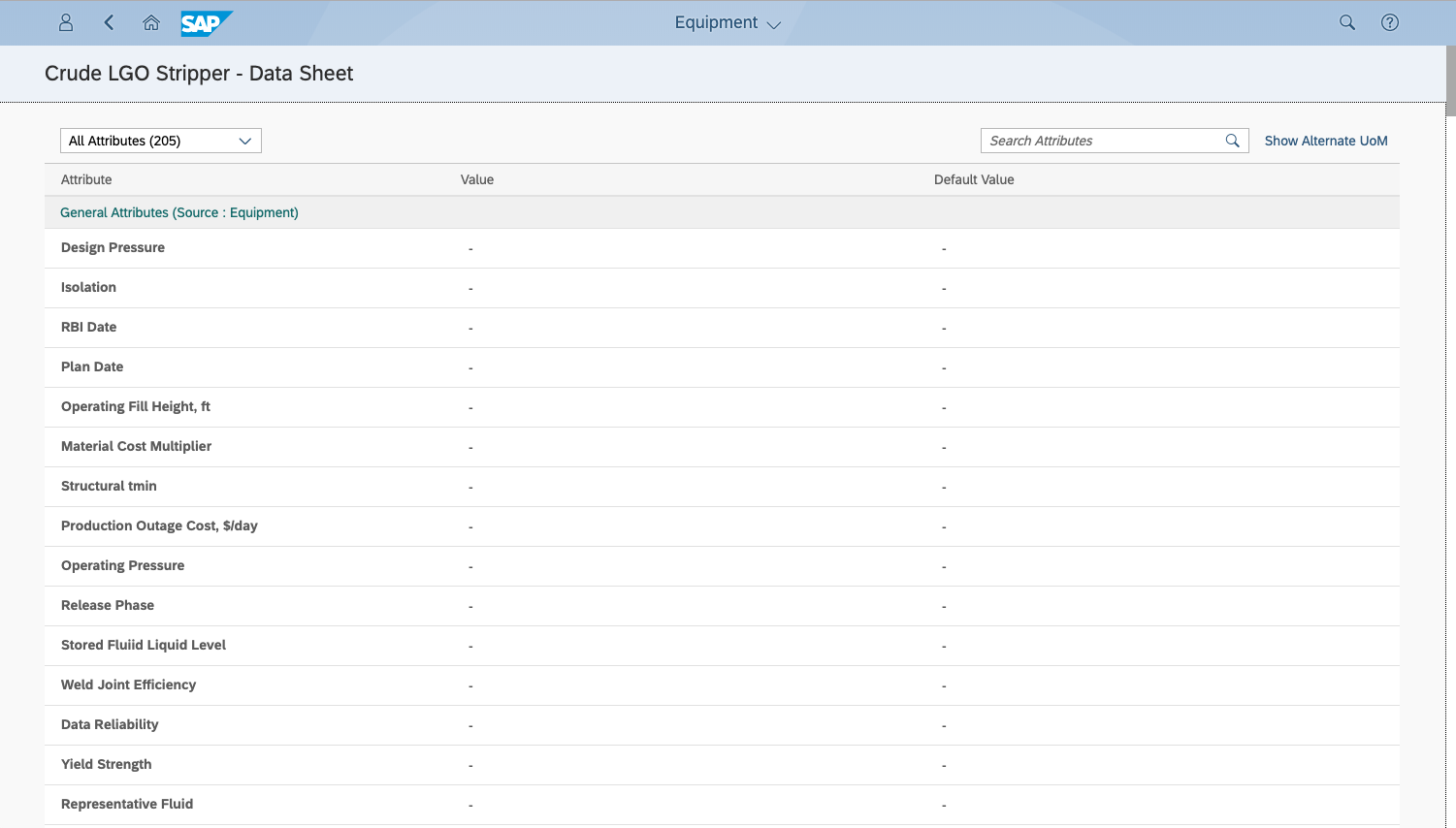

The data typically required for asset management include design, construction, process, risk and predictive Information, inspection, maintenance, and other condition assessments.

Most of this data currently exists in non-structured data such as hard copies, PDF files, or structured data such as MS Excel sheets or internally developed databases. In some cases, the operator will have purchased commercially available Off-The-Shelf (OTS) solutions to store the data in a structured and query able format.

All of these circumstances more than likely result in siloed data causing barriers to people responsible for aggregating the information. Preventing them from making tactical and strategic decisions in managing the physical asset to avoid safety, environmental, or production related incidents.

Solution

The SAP Master Data provides operators great flexibility and power to define the necessary data attributes and organize them into templates and models. The asset can also be physically represented in a rich asset taxonomy with Locations, Systems, and Groups.

The recent innovations with SAP Asset Intelligence Network have been extended to assessment templates for various analysis.

Software Components

SAP Asset Intelligence Network (AIN) - Optional for allowing equipment OEM’s and Service Providers to directly update your Master Data through a controlled process.

SAP Asset Strategy and Performance Management (ASPM) - Optional for Risk and Reliability and Condition Assessments data

SAP Predictive Maintenance and Service (PDMS) - Option for telemetry data management and analysis

AsInt CORE Risk Based Inspection (RBI) - Optional for Risk Based Inspection assessment and prediction data. Inputs and outputs are persisted as part of the SAP Master Data.

AsInt CORE Inspection for SAP (IDMS) - Optional for traditional Mechanical Integrity Inspections and Thickness Data Management.

AsInt Mobile CORE Inspection - Optional for data collection of Mechanical Integrity Inspections and Thickness Readings

Value to the Customer

By utilizing a single dataset based on the SAP Master Data, users of the information:

Will be able to connect-the-dots of the critical variables and events that occur on the asset.

Reduce IT and labor costs of managing multiple, and often lapping, data sources.

Provide a sustainable solution overtime.